Supply chain is an integral part of the manufacturing a product. This includes the journey from the retrieval of raw materials to the delivery of the finished product to the end user. As this includes the collaboration of various entities, viable data exchange, and operating advanced machinery, there are a few steps a manufacturer such as you must follow. Let’s take a look at a few key things to you should know about supply chain planning.

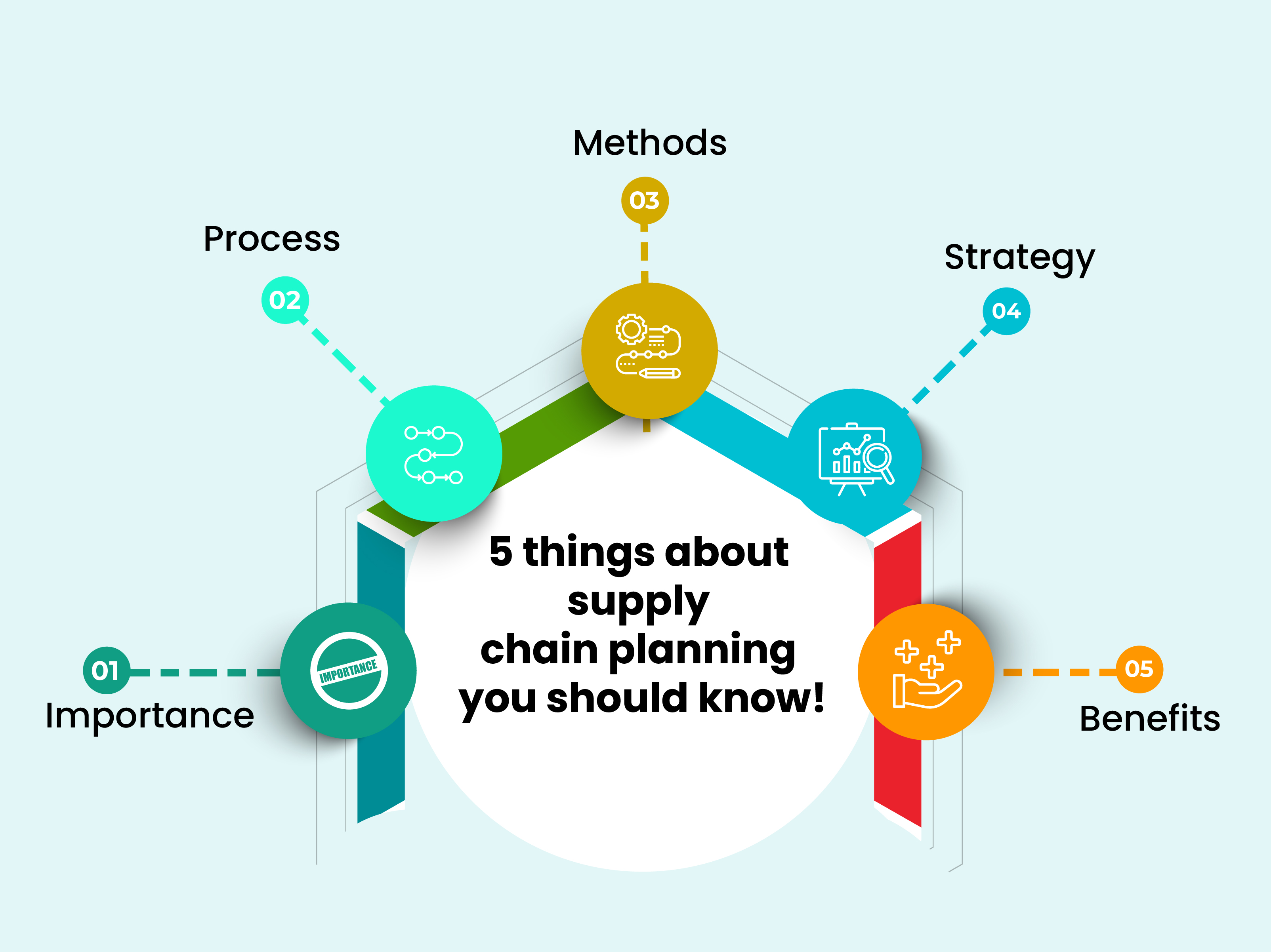

5 things about supply chain planning you should know!

1. Importance

Planning out a procedure from the start to the end is very important. Especially when it includes various businesses, assets, labour, machinery, and more. For example, you have a client who requires a thousand televisions by the end of the month. To do this, you would require many things, including raw materials, labour, transportation, etc. You cannot have labour working without materials, which follow the acquisition of raw materials. So, just having them is not enough, planning out the order of procedures is essential. Hence, this is an essential part of manufacturing.

2. Process

First, start by mapping out your entire production process, from the stage of design to final product delivery. Once this is done, the next pertinent thing to do is collect all the required assets and data to get production started. Based on logistics and other operations, you must decide whether to source locally or internationally, find shipping methods, etc. After that, the next logical step is to offer after-sale support for a good customer experience.

3. Methods

Though planning seems like just a set of procedures, the only way to get closer to the ideal manufacturing setup is by having a manufacturing strategy. This allows you to assess and improve each and every part of your product and enhance it. You can do this by using supply chain analytics. Read our blog about supply chain analytics & lean six sigma manufacturing to know more!

4. Strategy

Finding the problem areas with your production is a difficult process. Hence, where manufacturing strategies like lean six-sigma manufacturing, demand planning, digitisation, and standardisation come into play. These allow you to identify problem areas in the production and suggest solutions. Radiant tries and tests these methods in order to use the best one and provide the best products in the industry to our clients.

5. Benefits

The main agenda behind supply chain planning is to improve your production's efficiency by providing process transparency. By setting out a plan, you allow everybody involved, from the stakeholder to the worker, to understand their jobs and deadlines without any confusion. It is also helps the entities involved to carry out all the roles and responsibilities without any interruptions. Which is why many companies in the industry focus on planning before starting any production process.

As a manufacturer, we understand the struggles, challenges, and difficulties we face to create and design a successfully production system. Instead of doing all of this on your own, why not let the experts take the wheel? Here at Radiant Electronics & Appliances, we offer the best consumer electronics manufacturing services in India. Send us an email at info@radiantappliances.com or give us a call at +91-8414 667701 if you wish to employ any of our services.