Supply chain is a network of businesses and people that are a part of the production process. This includes everyone from the acquisition of raw materials to the delivery of the finished product to the end user. As there are numerous people and entities involved in this, it can get difficult to monitor each and every aspect. So, what do manufacturers do in such a situation? This is where the stability of the supply chain comes into play.

What is a stable supply chain in manufacturing?

The main reason many manufacturers aim for stability is that they understand its importance. A stable supply chain is pertinent to an efficient manufacturing setup. So, you might wonder how you can attain that without compromising on quality work.

The first thing to remember is that a stable supply chain does not mean a static supply chain. Changes are part of an evolving world, so refurbishing your business accordingly is not wrong. But applying all of them together can become chaotic. This is part of the reason why a supply chain becomes unstable. So, you might wonder what you can do in such situations. That’s why we have brought you the best ways to stabilise your supply chain with ease.

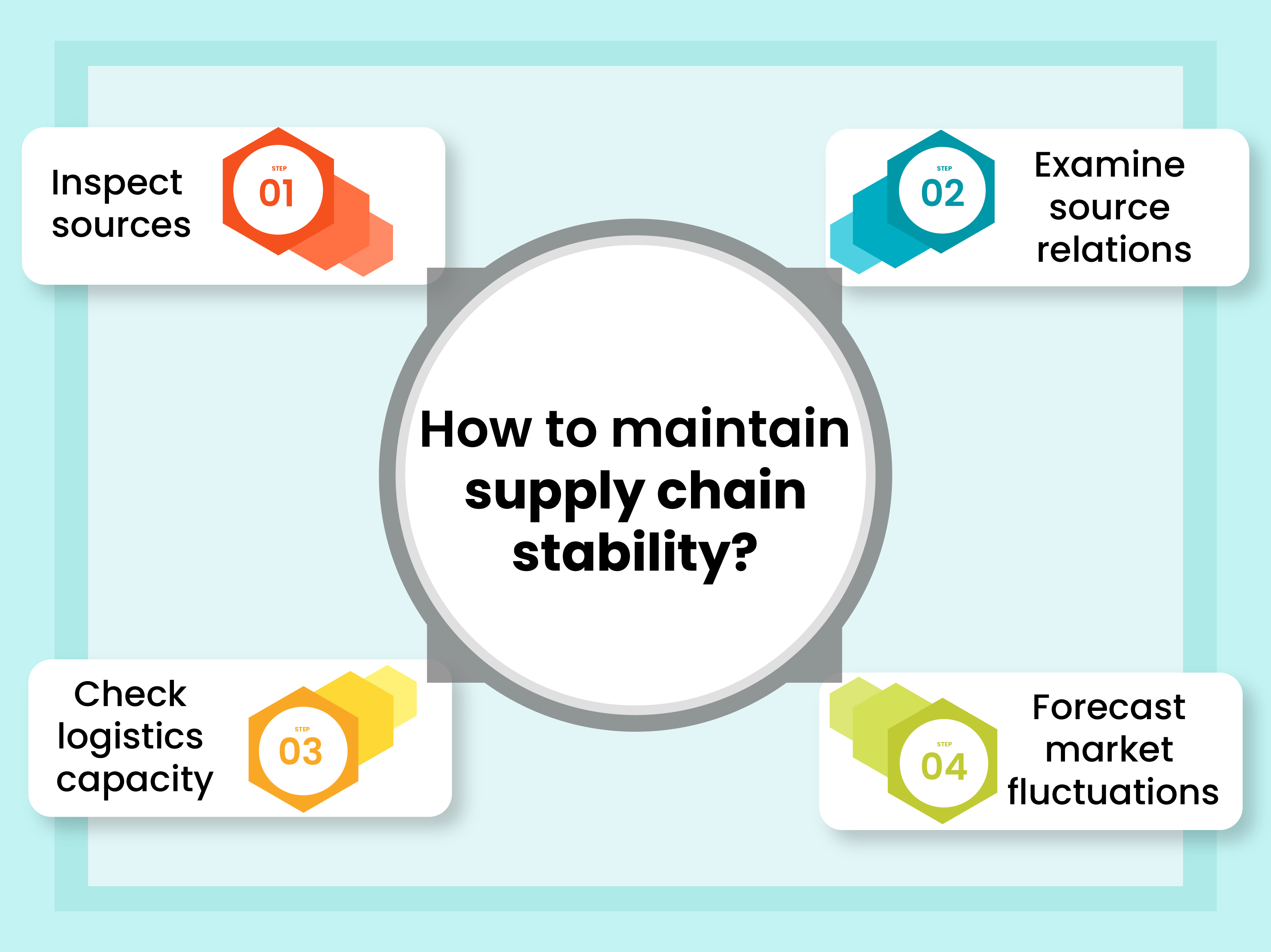

How do you maintain supply chain stability?

1. Inspect sources

Find out what sources and components are part of your supply chain. Once you have established this, organise them in a workflow order. This way, you can have a clear map view of the supply chain procedures. Based on this map, you can use lean six-sigma manufacturing or other similar strategies to improve the procedures.

2. Examine source relations

Just having vendors and business partners is not enough. Maintaining valuable relationships with them is also required for an undisruptive supply chain. For example, having great relationships with local vendors can be very helpful. This way, urgent orders or delays are easily fulfilled. Read our blog about the benefits of local sourcing for additional information.

3. Check logistics capacity

Work hand in hand with your logistics team to manage your supply chain. By keeping up-to-date with your logistics team, you can easily find the flaws and issues in your supply chain that are the cause for an unstable supply chain. Based on the received report you can make the required changes accordingly.

4. Forecast market fluctuations

Even if your entire supply chain is functioning efficiently, there will always be an obstacle that will cause supply chain disruption. The perfect example of this is the COVID-19 pandemic. Hence, being ahead of such a situation is essential. You can use various supply chain analytics available in the market today to do so. Check out our blog about supply chain analytics to know more.

The main reason many companies are focused on global supply chain stability is that it plays a huge part in maintaining manufacturing efficiency. Which is why in this article we have discussed different steps to take to avoid supply chain instability. To learn more about such industry topics visit Radiant Electronics and Appliances blog today!