A user’s main intent is always to get the best product in the least amount of time. Though numerous other factors come into play, these two take the lead. This is why we, as manufacturers, have to do our best to improve production so, our clients can have the ideal product they desire in no time. One such way is with the help of six sigma and lean six sigma manufacturing. So, let’s take a deep dive into what these are and how they can benefit the manufacturing industry.

What is six sigma?

The six sigma strategy follows the rule of elimination to improve production value. It involves 5 crucial steps: define, measure, analyse, improve, and control. Based on these five principles, the six sigma strategy is executed. A few studies also state that the implementation of this strategy has helped businesses’ success immensely.

What is lean six sigma in manufacturing?

Lean six sigma manufacturing is a tool that manufacturers use for quality control and process improvement. The key difference between lean manufacturing and six sigma strategy is that lean focuses on improving all aspects of the business. Lean Six Sigma combines both elimination and improving the overall aspects of production. So let’s take a look at what lean manufacturing includes!

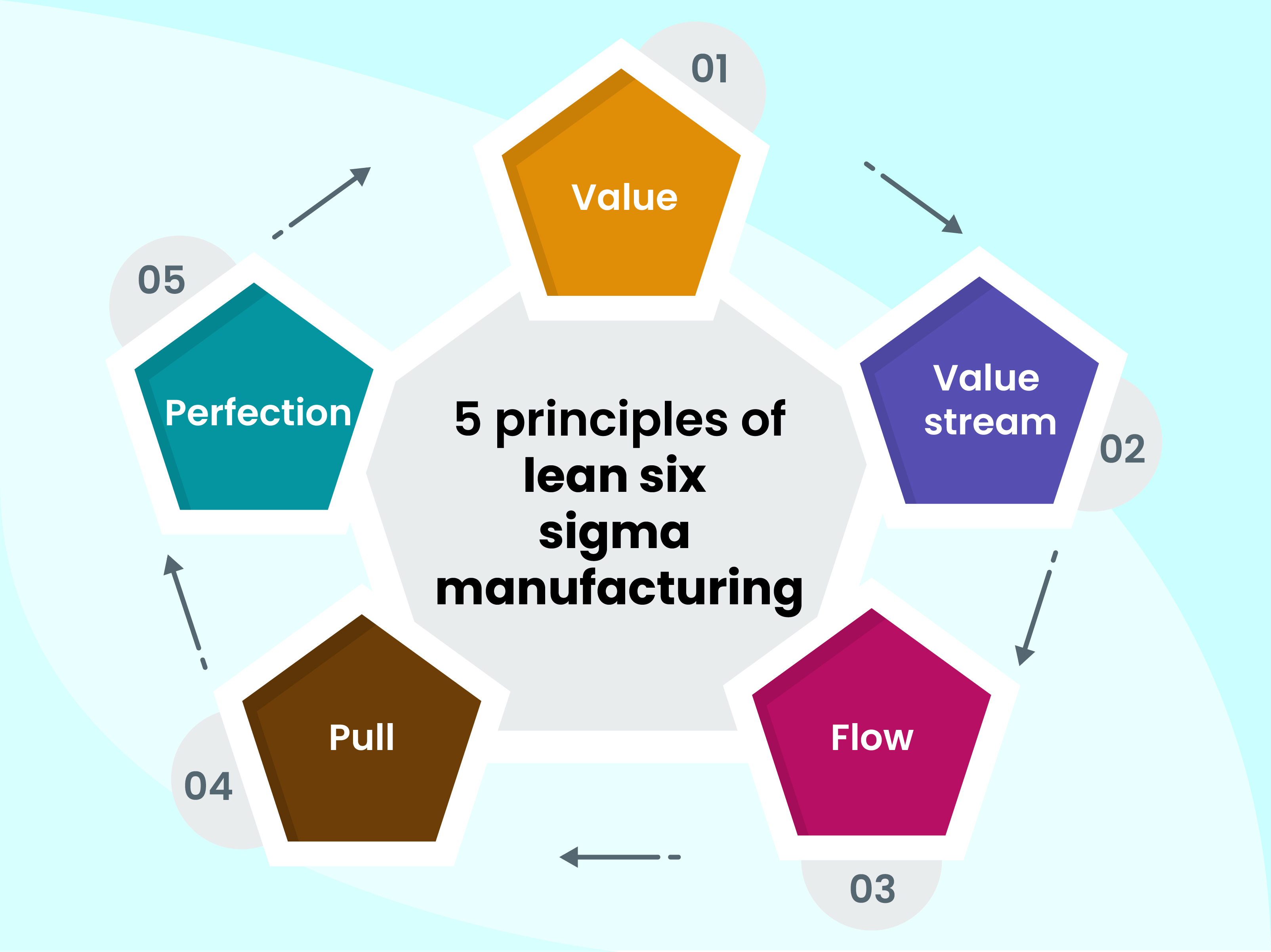

5 components of lean six sigma manufacturing everyone should know!

1. Value

Before eliminating any process or method from your production, the first essential step is to measure the procedure’s values. Some factors include a timeline, price point, and requirement or expectation. These help you understand their role in the manufacturing process thoroughly. One of the ways to determine the value of anything in manufacturing is based on the customer’s needs.

2. Value Stream

Once the value of each process is established, the next ideal step that follows is to streamline the procedures. That means, you will have to map out what you need and require by considering every essential factor that get effected by the decision. This includes everything from the beginning of design to delivery and after-sales support. After you have established the map, you can visually understand each of their role and what can be eliminated. This process continues with the elimination of unnecessary procedures.

3. Flow

When the cuts within the production process are completed, the you must head for the step that includes rearranging all the processes is a systematic order. Teh process should be done in such a way that, though there a few procedures missing, the efficiency of the manufacturing does not get affected.

4. Pull

"Pull" here refers to the customers receiving the products from us. As this strategy improves production, it also simultaneously improves time-to-market. This means that customers can "pull" the product from manufacturers as required without any delay. Which also implies setting up a strategy GTM to ensure time to market.

5. Perfection

After all the above steps are executed, comes the most pertinent of them, perfection. This can only be accomplished if the consumer can always get what they want. To do that, the updates must be dynamic rather than static. This ensures that the procedures are up-to-date and fully functional.

Fabricating a product is not an easy task. It takes tonnes of time and tedious work to get started, from the design to the finished product. Which is why we, as manufacturers, should do everything, we can to improve and enhance production from the start to the end. Lean six sigma manufacturing is one such perfect example that allows us to be as efficient as possible. Even at Radiant Electronics and Appliances, we do our best to use such methods to provide our clients with the best possible results. Visit our website to learn about similar tips and strategies that improve the production quality of a manufacturing setup!