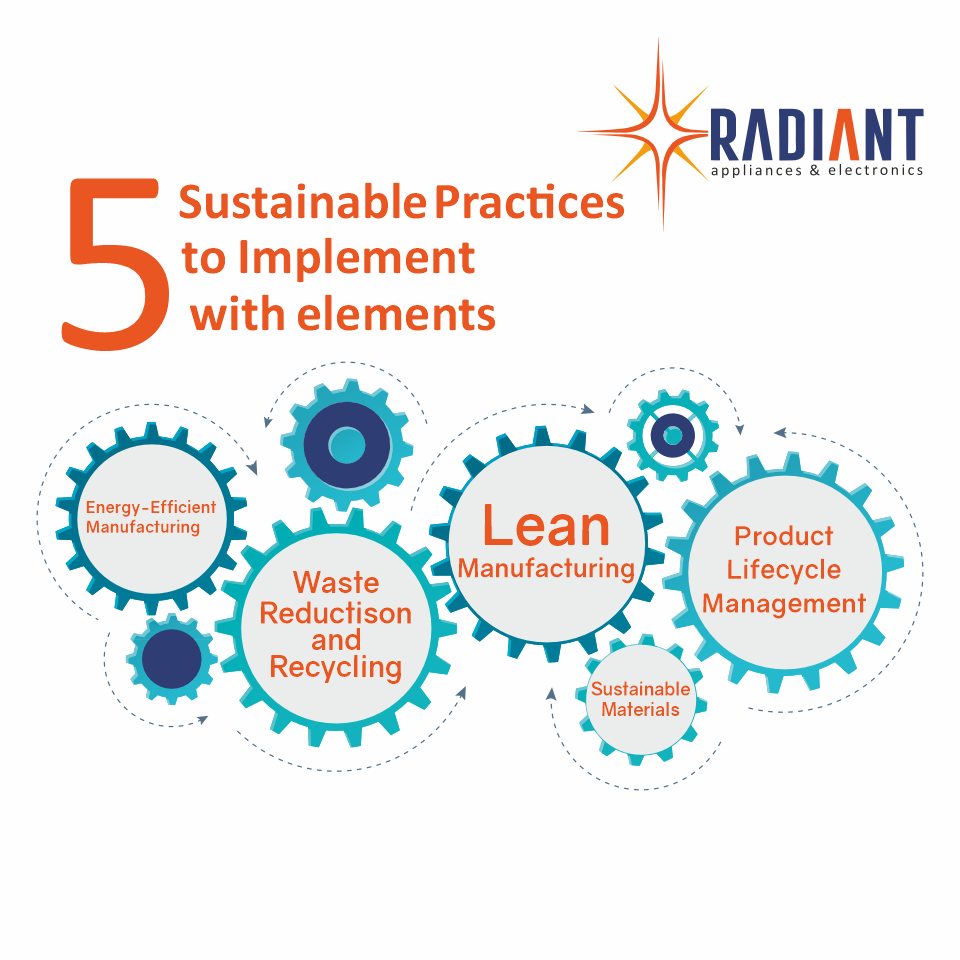

As the globe faces environmental issues in the twenty-first century, industrial organisations must make sustainability a core priority. During this period, the manufacturing sector must go through a "Green Revolution," or an enormous change toward ecologically benign processes that are both environmentally friendly and commercially viable in the long run. Here, we have curated a list of 5 most important sustainable practices for all manufacturing industries.

1. Energy-Efficient Manufacturing:

The energy-efficient comprises a variety of approaches, one of which is modernising equipment and production methods to help spend less energy. In this energy-efficient lighting solutions using LED light extend the life of lighting fixtures while also lowering electricity consumption and carbon footprint. Furthermore, solar energy can reduce the consumption of fossil fuels while allowing it to use sustainable energy. Manufacturers that use less energy improve their profitability and competitiveness while also conserving the environment.

2. Waste Reduction and Recycling:

Waste is a usual outcome of the production process in the manufacturing industry, however one should concentrate on reducing it. It is necessary to implement efficient waste reduction techniques and recycling systems to lessen the detrimental environmental effects of production processes. Many common industrial materials, including metals and polymers, can be recycled and used again. This contributes to the manufacturing industry being more environmentally friendly and sustainable by preserving significant resources and decreasing the requirement to gather and process new raw materials.

3. Lean Manufacturing:

The efforts to achieve sustainable development are centred on lean manufacturing principles. Manufacturing companies can reduce waste such as excess inventory, overproduction, and wasteful transportation to streamline processes, consume fewer resources, and increase overall efficiency. Lean approaches are a win-win strategy since they provide financial as well as environmental benefits.

4. Sustainable Materials:

In the manufacturing sector, using sustainable resources is a crucial part of green production. One can choose environmentally friendly components like recycled or biodegradable materials to decrease the negative effects of their products on the environment. To lower transportation emissions, supply chains can also be looked at for local material sourcing.

5. Product Lifecycle Management:

Sustainability covers the whole lifecycle of a product, going beyond mere production. From design and production through distribution and disposal, manufacturers should take sustainability into account at every step. A less environmental impact is ensured by designing things to be long-lasting, simple to repair, and recyclable.

As a result, the manufacturing sector must embrace the green revolution now; it is not some far-off ideal. By adopting sustainable practices including energy efficiency, waste reduction, lean manufacturing, and ethical material procurement, the manufacturing sector plays a significant role in fostering a more environmentally friendly future.

These green revolution methods keep the sector prospering while also making it more ecologically friendly. Based on this sustainable practices knowledge, you can select the technique that best suits your industry. Visit our Radiant Appliances & Electronics page for additional information on manufacturing. You can also reach us at +91-8414667701!