Automation in manufacturing is about enhancing machinery with new and modern technology. According to market research, the automation market’s size was USD 205.86 billion in 2022. It is also known to increase up to USD 395.09 billion by the end of 2029. Based on these statistics, we can say that automation is not going away anytime soon. In fact, it is to expand further into a bigger market with copious opportunities and trends. So, let’s take a look at what the new generation of technology has in store for the future.

Why should automation be part of manufacturing?

Technological advances have always been a controversial topic in the manufacturing industry. Contrary to popular belief, automation technology is in fact creating more opportunities. At the end of the day, even if we used fully automated machines, we would still need labour and automation engineers to oversee them. This means these would lead to tons of job opportunities in manufacturing. If you are wondering what this automation is, then keep reading.

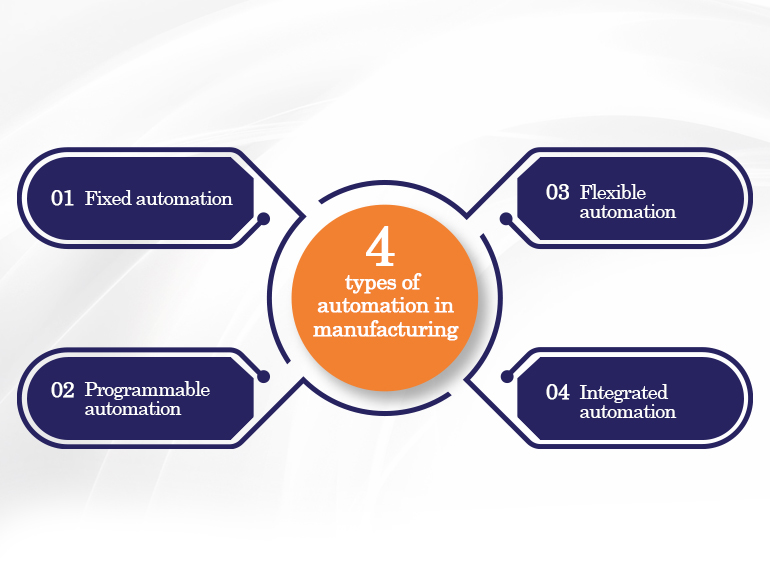

What are the 4 types of automation in manufacturing?

1.Fixed automation

Fixed automated refers to machines that perform the same function throughout manufacturing. Manufacturers also refer to this as hard automation. This is because its system carries out only a fixed set of tasks without deviation. Such advanced machinery is generally used in repetitive manufacturing processes where robotic process automation (RPA) is not required.

2.Programmable automation

When you need small changes in the functions of the automated machine, you can use programmable automation. Mass production is where this technology is most effective. Small changes to the code of the machine will help the machine to perform tasks. This is because it only requires small changes close to the original operation for them to finish the task.

3.Flexible automation

A robot can perform various functions based on a sophisticated program. This is well known as flexible automation. Here machines receive code from a human-operated computer that allows them to perform the relevant task. These codes are generally changed to match the product fabrication. As they have the ability to perform tasks based on changing codes, it is better to use them in production which requires more customization.

4.Integrated automation

Integrated automation is where the entire production is smart automation system that works with little to no human supervision. Their key functions would include computer-controlled scheduling and production line control processes. Such functions are helpful in production processes like batch and continuous process manufacturing.

When it comes to automation, at Radiant Appliances & Electronics, we do our best to incorporate modern technology into our work. This is so our customers can get the best in the least amount of time. Alongside that, with automised production, we are able to provide the best care for our workers. We are able to reduce workplace hazards and increase job opportunities. If you are looking to work for or would like to use our services, contact us through our email at info@radiantappliances.com.