Many people believe that the carbon footprint is the only source of unsustainable environmental practices. Though it plays a role in environmental sustainability, it is not fully responsible for the uninhabitable Earth. So why are so many people around the world, including the manufacturing industry, focusing on reducing their carbon footprint during their production process?

To understand this, first, we have to understand the concept of the greenhouse effect. It is the phenomenon where certain gases trap heat within themselves, thereby keeping our atmosphere warm rather than allowing the heat to escape into space and render Earth uninhabitable. Though this is a naturally occurring process, because of phenomenon such as the burning of fossil fuels, heat production has heightened. This has led to high emissions of greenhouse gases and higher chances of heat being trapped. A study states that, among the emitted CO2, 40% of it stays as it is in the atmosphere for over 100 years. Which means that it can cause damage to the atmosphere for longer. Therefore, taking action to reduce your carbon footprint is essential. Here's what manufacturers can do to reduce your carbon footprint.

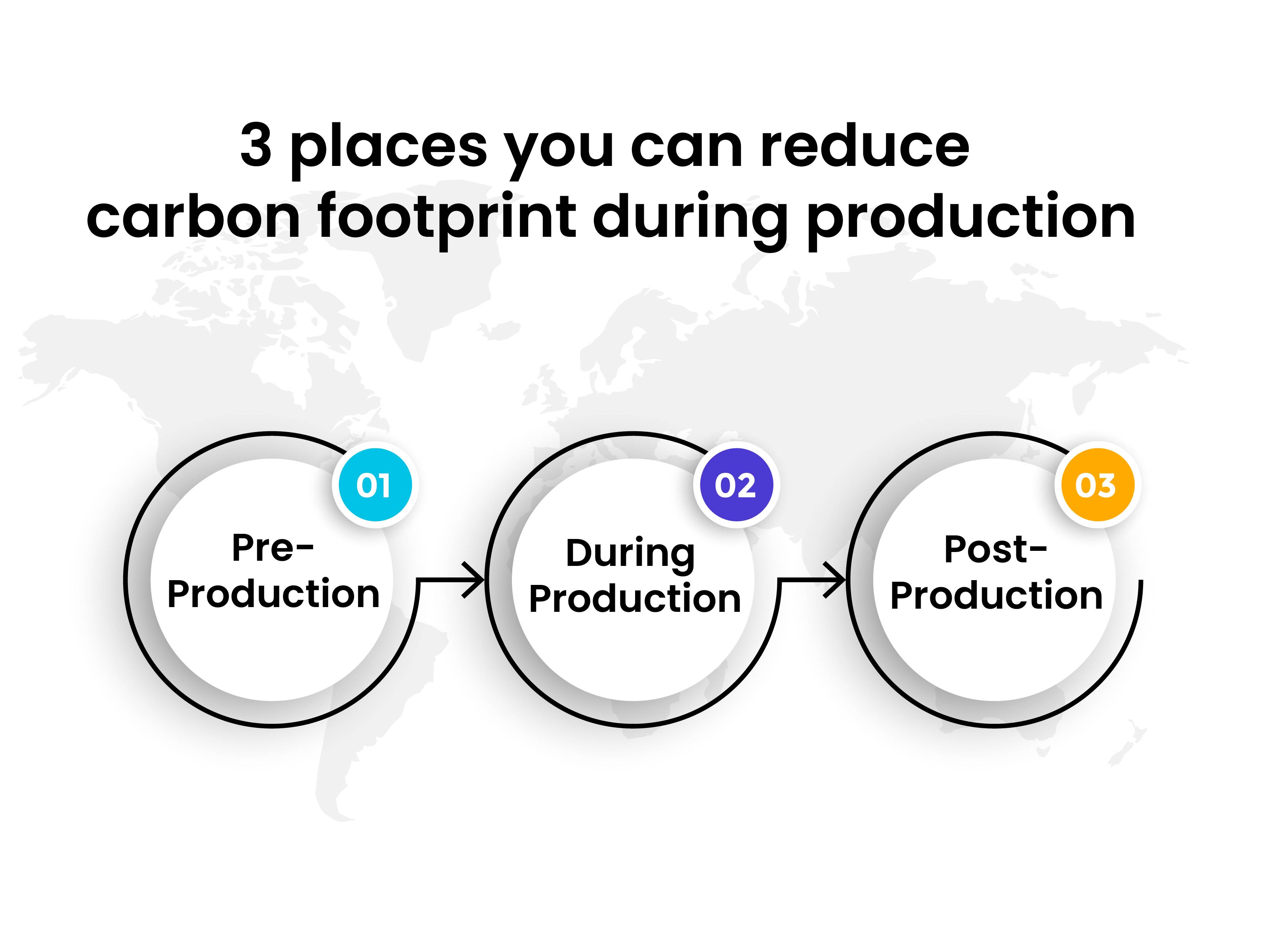

3 easy ways to reduce carbon footprint in manufacturing!

Pre-production

Start with the basics, which are the acquisition of raw materials. Simply by avoiding global sourcing and relying on local vendors for raw materials, you are saving money and lowering your carbon footprint exponentially. This includes carbon produced during transportation, storage, etc. You can also implement eco-design engineering as part of your design process during manufacturing.

During production

While fabricating any product, we as manufacturers use raw materials such as water, energy, and many others. The best way to reduce carbon dioxide emissions is by controlling the above-mentioned factors. You can control water supply as well as energy supply, which will have a huge impact on your production's carbon footprint. You can also use green energy, that is, solar energy or hydropower, which have a zero-carbon footprint when compared to fossil fuels.

Post-production

Even if you have a well-oiled production setup with the lowest carbon footprint, post-manufacturing is a different story. It is where we dispose of waste materials that are not being used in the manufacturing procedure. Some materials, such as steel, cardboard, and others, can be reused and become advantageous for you.

Even though we are well aware of the damage caused by these gases to the environment, what matters most is taking the appropriate actions. This is the only way we can ensure the sustenance of the human race for the future. As a result, at Radiant Appliances & Electronics we do everything we can to reduce our carbon footprint and contribute to the environment. To know more about the different ways a manufacturer can contribute to society, visit our blog today!