Manufacturing is an essential part of every industry that fabricates goods. It is the process of converting raw materials into final products with the help of machines and manual labour. This process usually includes idea formation, planning, forming a prototype, and finally production. Though it seems simple, the process includes many intricate steps and procedures. Here is a brief on different methods of manufacturing and their respective benefits.

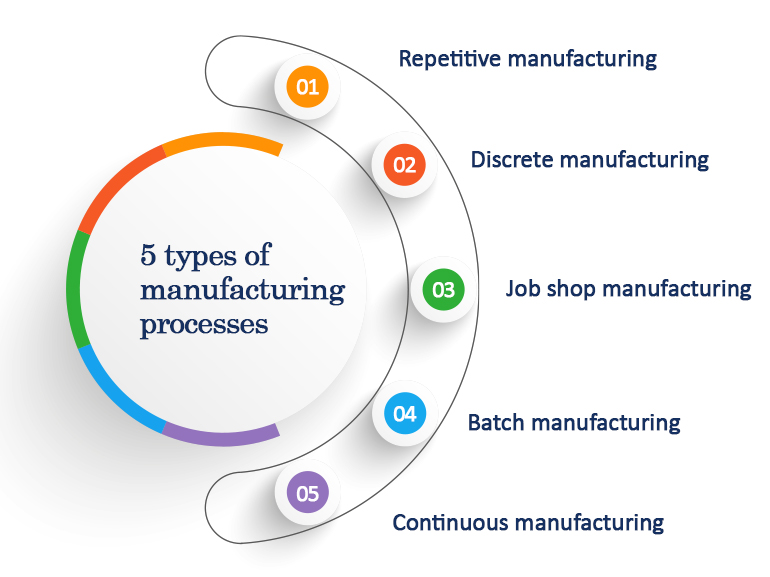

Every industry uses a different method as each company has a different set of requirements. Based on that, there are five manufacturing processes.

1. Repetitive manufacturing

The repetitive process is a method that makes the same product repeatedly. This is widely practised in industries such as electronics, appliances, automobiles, etc. It is popular since there are no restrictions on product quantity or timing. One of its important characteristics is that we can have lower labour costs with the help of automation.

2. Job shop manufacturing

When it comes to customised or personalised products, a Job shop is the best way to go. Due to the customisation element in each product, the layout for production will change accordingly. To make this part more efficient, we have small stations. These stations include equipment and essentials used to perform a certain function. So, when a new order comes in, each product can be developed in their respective stations based on the equipment or operations required. A few of the key advantages of using this method are flexibility, highly skilled workers, better scope for change, and more.

3. Discrete manufacturing

Discrete manufacturing is very similar to repetitive manufacturing. The main difference between them is that in discrete fabrication, the products will change frequently. The procedure involves many stations and sub-stations. Each substation includes identical equipment or gear to accomplish similar functions. One of the benefits of this strategy is that each station’s work can start at any time without any correlation to other stations. This way, we can put the components together to create the final product instead of waiting for them to be developed one by one. The industries we see this more in are automation, furniture, toys, electronics, and others.

4. Batch process manufacturing

Products such as clothes, baked goods, chemicals, and more are usually made using the batch method. Here, similar products are made in batches altogether instead of one by one. This is most commonly used because of its cost-friendly nature, high efficiency, low wastage, etc.

5. Continuous process manufacturing

The continuous process is the exact opposite of batch production. If you are looking to produce a product in high volume without any customisation, then this process of manufacturing is the way to go. We can use the continuous method of production to develop goods such as paper, pulp, petrochemicals, oil/gas refineries, and others. High quality, low risk of human error, and time-effectiveness are a few advantages of using this method in product fabrication.

In recent years, the manufacturing industry has gone through a sea of change. Modern technologies such as AI and machine learning have transcended into the production process, increasing its efficiency. As such trends keep arising every day, it has become hard to keep up with them. You can visit our blog at Radiant Appliances & Electronics.so you can learn everything you need about manufacturing and its trends.