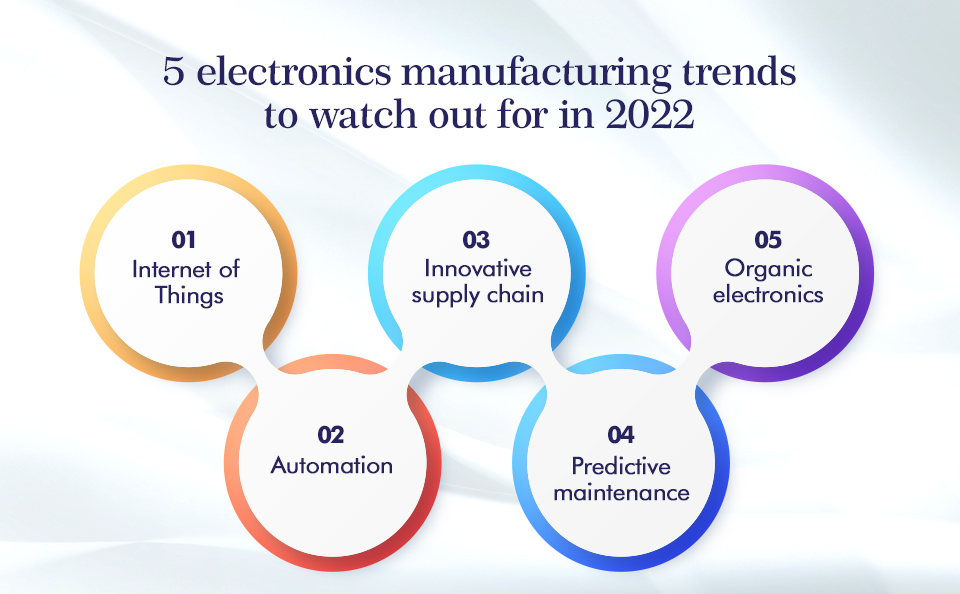

Despite the pandemic-induced economic slowdown, technological advancements played a significant role in the growth of the electronics manufacturing sector. Smarter manufacturing practices have been the biggest driver of this growth. We intend to explore five trendsetting developments in this article today.

Internet of Things

The electronics manufacturing industry can leverage the Internet of Things (IoT) for unprecedented growth opportunities. The IoT allows electronic manufacturing units to be digitally connected while storing and processing information without external support. The IoT can improve efficiency, security, cost-effectiveness, and product innovation.

Cloud computing, smaller censors, and the growth of the Internet have prompted IoT’s lead in the race of emerging technologies. With everything in place, you can have real-time data at your fingertips to make informed business decisions.

Automation

While complete automation in the electronics manufacturing sector is still a distant dream, various automation technologies have made production trouble and error-free. These technological advancements in automation includes smart factories, manufacturing robots, and the smart supply chain management system. These automation systems in conjunction with IoT devices create an efficient manufacturing operation.

Innovative supply chain

As businesses strive for better products and spend less while doing so, the best way forward is to innovate supply chain management. This trend aims at improving the logistics to revamp the supply chain, which, in turn, can significantly reduce costs in several key areas. This allows electronics manufacturers to be more agile in their operations and thus be more open to fluctuating market demands.

Predictive maintenance

Any manufacturing company’s smooth operation is entirely dependent on its types of equipment. Because if they break down the entire operation comes to a halt and so will your revenue generation. However, using AI and IoT data collection, you can accurately identify problem areas before they happen. This helps electronic manufacturers avoid downtime and plan maintenance at a convenient time. Identify a cost-effective manner to conduct repairs and include the same in your budget. A trend like predictive maintenance removes any scope of surprise downtime, thus improving the efficiency of your manufacturing operations.

Organic electronics

Organic electronics has become a market rage in recent times owing to its efficiency, low cost, flexibility, lightweight, indissoluble nature, and optical transparency. Additionally, the demand for environmentally friendly production and sustainable development is growing, prompting electronic manufacturers to choose organic electronics. One of the most significant trends in electronics production is the creation of gadgets using biodegradable and recyclable materials or designing circuits with microbial components. The use of organic materials in producing electronic devices also permits the use of safer and readily accessible raw materials. As a result, it gives organizations new business opportunities, while being environmentally responsible.

The electronic manufacturing trends discussed in this article pave a path for smarter, efficient, and cost-effective practices. The use of advanced technology and materials can help you achieve this. Apart from the five trends discussed here, we'd also like to mention printed electronics, Artificial Intelligence, immersive technology, and 3D printing. These evolving technologies only point to a brighter future. For more information on the electronics manufacturing process, get in touch with the experts at Radiant Appliances & Electronics.