Logistics is part of the supply chain management process that oversees all the procedures within the company. Whereas the supply chain oversees all the processes within the company and its partners, and collaborators, manufacturing logistics deals with procedures from acquiring raw materials to product creation. Many things happen during this process that can alter the course of production, so let's look at what logistics in manufacturing is and why it's important.

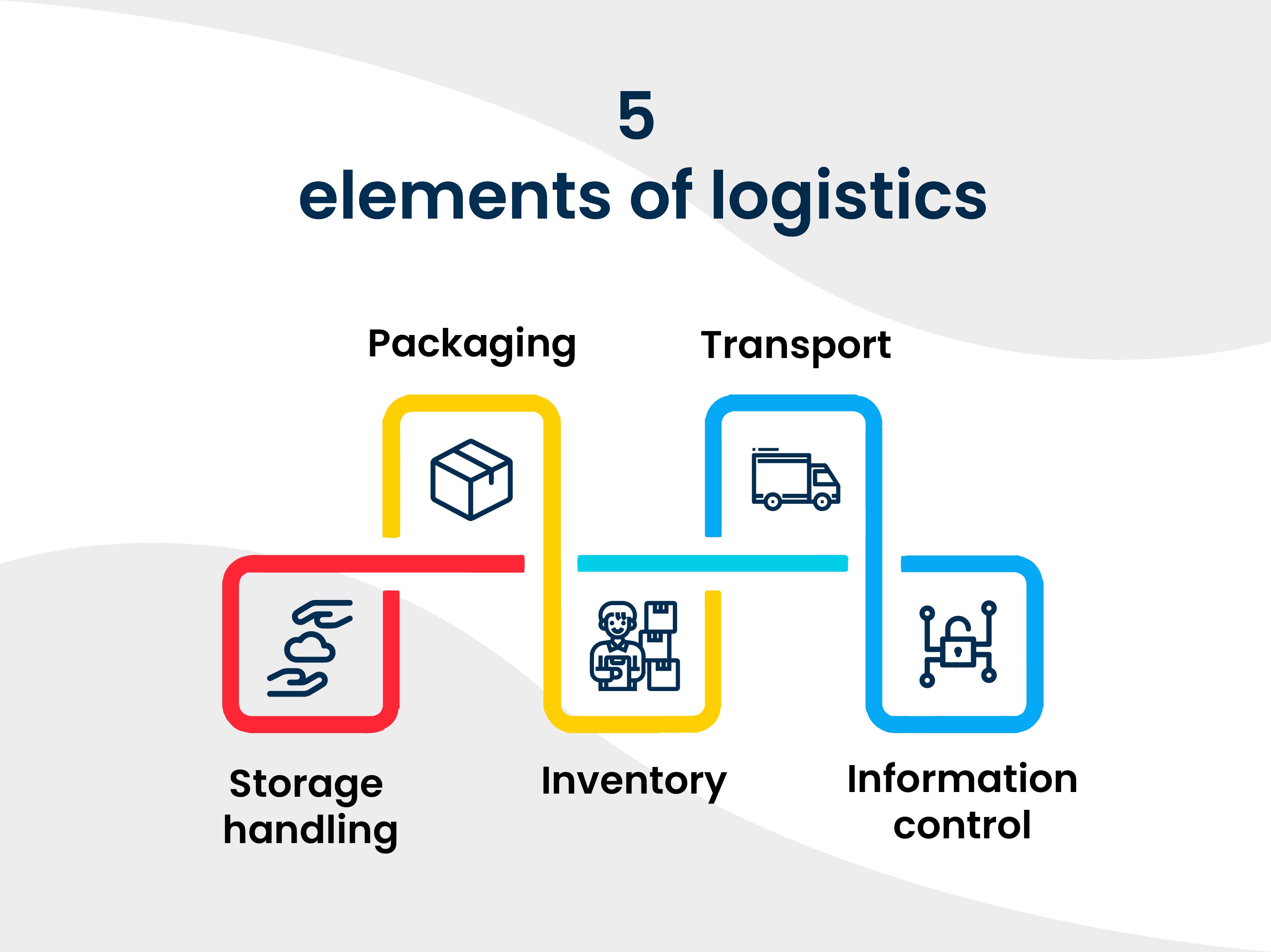

What are the elements of logistics?

1. Storage handling

Any and all maintenance regarding raw materials from shipping to storage falls under this category. Usually, there are appointed administrators whose job is to ensure that this management is functioning properly so there is no delay in product fabrication.

2. Packaging

This is an important step, especially when you are fabricating fragile goods made of glass or paper. To ensure the materials do not break during transportation or delivery, the packing step must be done carefully and effectively.

3. Inventory

We have previously seen why inventory management is essential in the supply chain. By using interesting methods such as supply chain KPIs, demand forecasting, inventory planning, and others, we can create a well-functioning inventory management system that ensures you have all the essentials for your product creation.

4. Transport

The first thing that comes to mind when we think about logistics is transportation, also known as delivery. Without this, there is no point in making a product when it cannot reach the end user. Which is why it is deemed the most important element of logistics.

5. Information control

Just knowing the names of your suppliers is not enough. Knowing them and their company will allow a transparent flow of communication. This way, there are fewer chances of inconveniences arising in the future.

What is the importance of logistics in the manufacturing industry?

Logistics, in simple terms, is about having exactly what we need at the right place and time to create a product and deliver it to the customer. For example, in the consumer electronics manufacturing industry, logistics involves managing storage facilities, distribution centres, raw materials, transportation, etc. An efficient logistics management system has numerous benefits, including cost reduction. Which is why we need it as part of almost every manufacturing system.

What are the benefits of logistics management?

1. Highly efficient

2. Lowers operational costs

3. Increases demand through efficient productivity

4. Includes planning & preventing manufacturing disruption

5. Reduces the carbon footprint of your entire production

Every part of manufacturing plays a crucial role that results in an efficiency in your production process. Which is why logistics management is crucial. Even at Radiant Appliances & Electronics, we understand the value of logistics management, which is why we have a team dedicated to ensuring the logistics run as smoothly as possible. To know more about such industry-related topics, visit our website today!