Manufacturing process analysis: Steps & benefits you should know!

Process analysis has been deemed to be a huge part of the business process over the past two decades. It is a step-by-step review of all procedures that is required to perfect a task. So, you might wonder, why would you require a detailed report or study about a task?

Many studies are usually conducted to either improve or pull data from a project. This allows the project’s participants to thoroughly understand the ins and outs of the procedure. It not only provides valuable data about the task but also allows you to get the right insights into the procedures and a chance to improve their function for optimal output. So now we will find out how process analysis is beneficial in manufacturing!

What is manufacturing process analysis?

Every manufacturing process includes several steps of procedures, management, acquisition, and more. With each of these steps comes its fair share of challenges and problems. These can result in production failures and the product not reaching the market on time. As we have learned in the previous blog, “time-to-market” is essential for manufacturing. Today we will learn about how we can ensure that the manufacturing process is successfully completed without any delays with the help of manufacturing process analysis (MPA).

What is the importance of manufacturing process analysis?

TToday, we are using every possible technology to enhance our work without compromising on quality. Besides this, AI & ML technology also help in retrieving valuable data. But what is the value of this high-quality data if it cannot be used?

Smart manufacturing allows us to store and retrieve as much data as possible. This means that years’ worth of information about inventory, logistics, operations, transportation, and others are available within a few clicks. But these are only helpful if we can improve the existing production process. Which is where the manufacturing process analysis comes into play. It uses the data collected by AI & ML and puts it to use by finding cracks within the processes. This way, you can easily make changes were needed and create an ideal manufacturing system.

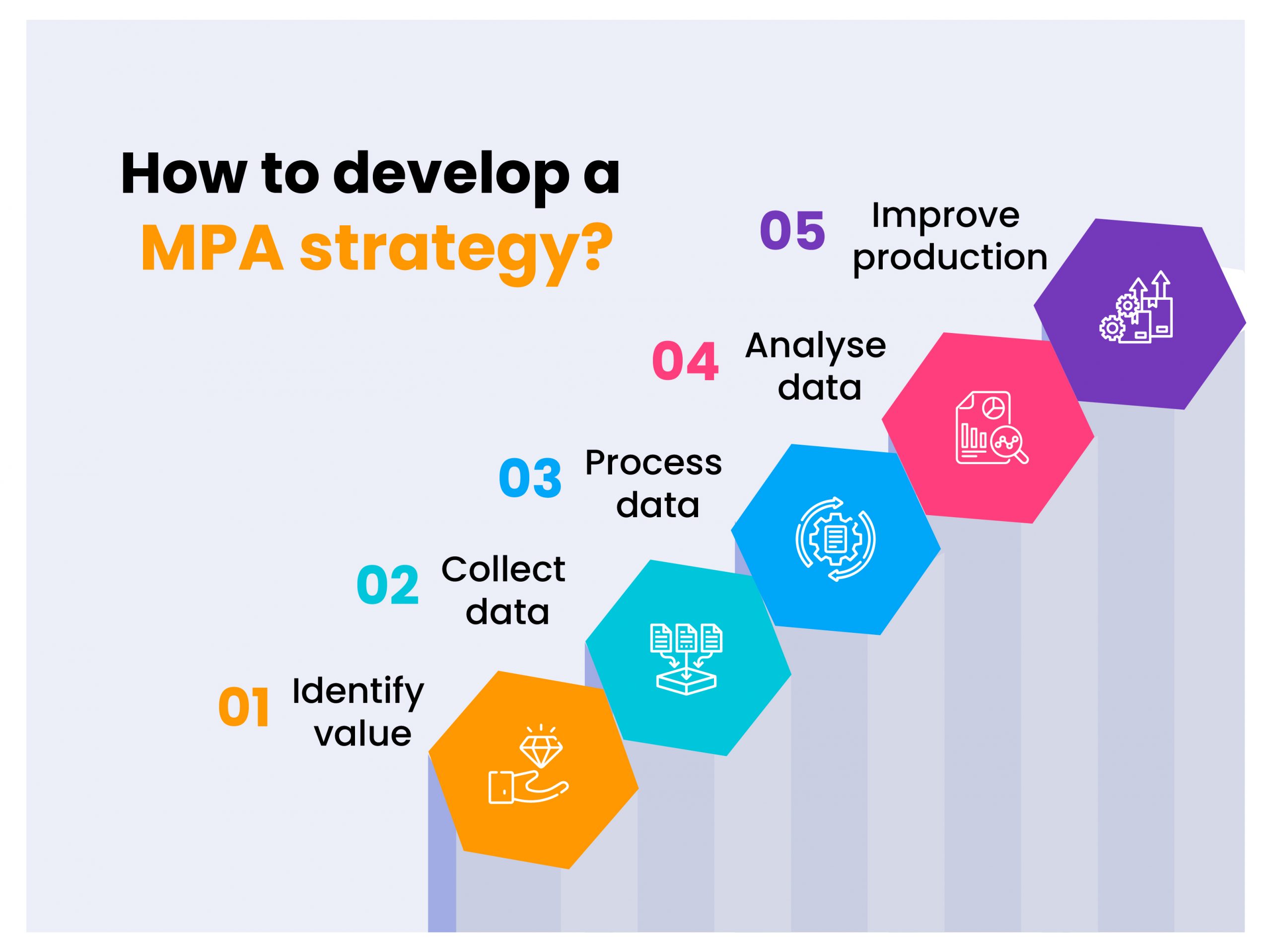

How to develop an MPA strategy?

Identification of value: Find what is relevant and essential for the sustenance of your production procedures.

Collection of data: Find out various data about vendors, inventory, and others and create a data platform.

Processing data: Process the found data and segregate them based on their relevance.

Analysis of data: Analyse the manufacturing process based on previously collected data and create a report.

Improve based on collected data: Make the required changes based on the MPA report to design an ideal manufacturing setup.

The main reason we focus on changes in the manufacturing industry is because of the ever-changing market. As people change, their desires about what they need change as well. To stay on top of these demands, you must be able to change your existing methods. Even if these methods have benefited you throughout the year, they might not be as useful now. Which is why processes like MPA are known to be helpful. To find out more about such similar industry topics, visit the Radiant Electronics and Appliances blog today!