What is the importance of value chain & it’s components in manufacturing?

A value chain is a step-by-step procedure taken by a company to deliver a product within a given time period. Each step taken plays a crucial role in ensuring the product’s fabrication without compromising its quality. The analysis of these procedures that adds value to your manufacturing process is known as value chain analysis.

Why does the manufacturing industry require a value chain & its analysis?

Many people wonder why would they need value chain analysis, especially when they have supply chain analysis. When it comes to supply chain analysis, you examine the overall procedures based on previously existing data and provide inputs. Whereas in value chain analysis, each and every step throughout the production process is studied and a detailed report is made. Based on this report, you can make valuable changes to the manufacturing procedures and gain optimal output.

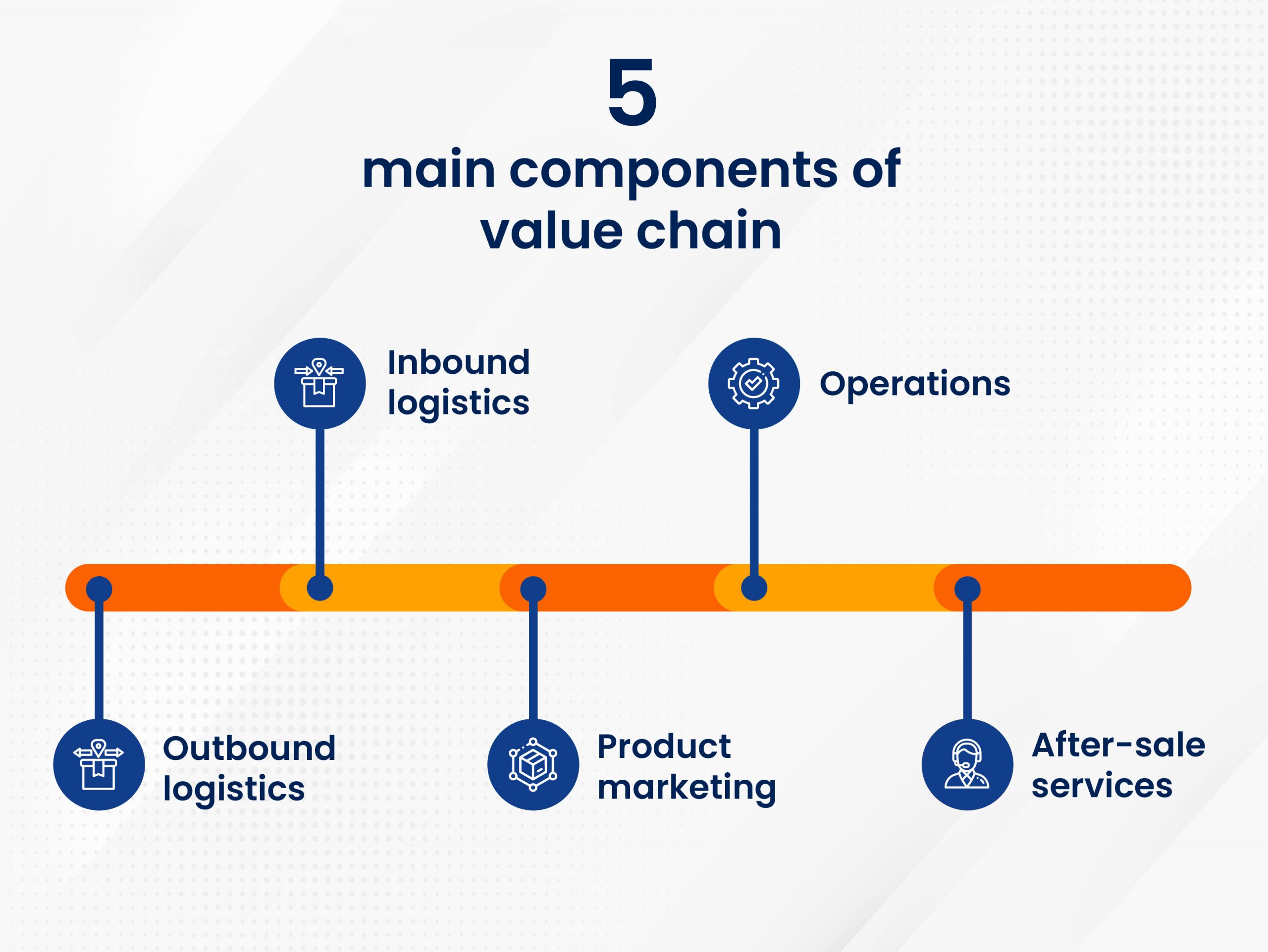

What are the components of the value chain?

Inbound logistics:

For any production process to begin, the first thing that comes after the design is acquiring raw materials. A list of these is documented, along with information regarding the vendors. These products are later received from the vendors and stored in a warehouse.

Operations:

Once you have received the raw materials, the next logical step will be to begin the production process. In this process, you can oversee see everything from product fabrication to assembly as well as packaging.

Outbound logistics:

The most important part of any production is product distribution. You need to ensure the products are ready to go, along with transportation arrangements, safety, etc.

Product marketing:

Even after you’ve sent out all your products. It is important to market your products to increase your customer base. Many people use various marketing agencies to ensure that they can get the best results.

After-sales service:

One of the best ways to innovate is with the help of customer feedback. By understanding the end user’s problems, you can improve your product and increase its value. Besides these, after-sales service is also great for increasing a company’s ROI.

Besides these, the value chain also has supporting components such as procurement where taking care of orders will take place. It also includes technological advancements, HR management, and company infrastructure as a part of the value chain to ensure that the work is completed in an optimal way manner.

Along with understanding the role, the value chain has in manufacturing, it is also important to know how to improve it. This is where the value chain analysis comes into play. To know how and what it comprises, check out Radiant Appliances & Electronics’blog. Here you will find various manufacturing and supply chain-related topics. If you are interested in our work or have any queries, contact us now through our email info@radiantappliances.com